Find out the quality of this rugs

The CompanyThis company began its activity in 1882. In the mid-nineteenth century the modern high quality rug began to attract interests, creating for the firm the opportunity to start a new project dedicated to the manufacture of design carpets which could meet the demand of the Italian market. Today the company is specialized in the manufacturing of Vintage patchwork carpet, a new and innovative production process in which old carpets are given new life, by first bleaching them and then re-dyeing them, with nuances which recall the original ones or with totally new colours. |

Vintage patchwork carpet

The Vintage collection was created with the aim of re-using and giving new life to old or antique carpets.

These carpets, coming from Iran or Turkey in Sivas Malatya area, are bleached through sun exposure, cut and then re-coloured and re-sewn with original sewing techniques. Patchwork is a form of needlework which involves sewing together different pieces of fabric.

The re-sewing process allows to apply new and modern colour nuances - such as violet, or the tones of black or grey - to classic and antique carpets, still bearing their original message. In this way tradition combines with innovation adopting new tones and concepts. Thanks to this particular manufacturing process, which is the result of the company's wide experience gained in the East markets, each rug is an original piece of work.

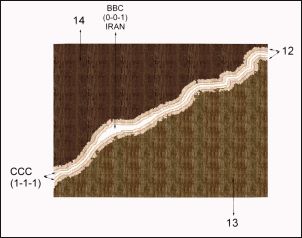

Hand-knotted carpetsThe rugs of this company are hand-knotted using thousand-year-old manufacturing techniques: the wool is harvested on the south-central Iran plateau. The wool is hand-spinned in every thread. The colouring process uses vegetable-based dyes. Together with the handmade spinning this allows to obtain unique shades and tones, thus avoiding the wear of wool through time. The weaving is made on wooden frames, by using cotton as a layer on which the weaver makes the drawer, following a printed scheme. Once the fabric has been weaved, the carpet, with a thickness of 50 mm, has to be shaved to reach the standard height of 10 mm; this process gives the rug a soft and bright look. At this point an anti-skid silicone rubber layer is put on the rear side of the carpet, which is then washed with water and soap to remove wool impurities. |

||||

|

|

|

|

|

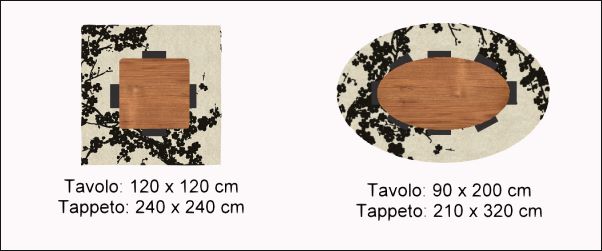

Custom-made CarpetsThe high personalization of these rugs allows to design wholly custom-made carpets which will enrich any environment in a different way.Their measurements and shape can be adapted to the furniture item of the room: tables, sofas or beds can influence the size of the carpet. This company can design highly customized rugs to match any table, whatever its shape or measurements are. Oval, round, square, rectangular or shaped tables; with small or big sizes, on diotti.com it is possible to create rugs suitable to meet any need. It is possible to have rugs matching the shape of the furniture items they refer to - as shown in the side photo in which rug and table share the same square shape - or with a total independent shape. |

|

|

|

|

The serviceThe company will develop a photorealistic render image in case of custom-size carpet purchases to show the customer its final shape and measurements, allowing a proper examination of the chosen rug. This render image will be sent per e-mail to the customer allowing a direct communication between manufacturer and buyer.These carpets offer also a wide colour customization: at the time of configuration it is possible to choose the colour code to assign to the purchased rug. The 8-week production time guarantees the apply of a handmade manufacturing technique for an extremely high quality result. |

|

|