How a Wardrobe is Made [GUIDE]

Buying a wardrobe for a bedroom is not a routine purchase, in fact we often only do it once in our lives. So it's important to inform ourselves on how each wardrobe is constructed, what materials are used and generally on the quality of the piece. In order to choose a model which is best suited to your specific needs, you need to be aware of all the different types on the market.

This is the only way to be sure that you are purchasing the right wardrobe for you, which hopefully will last you a lifetime.

So, how can you recognise a high-quality wardrobe?

How are they made and what are the main types?

In this video, we will look at:

- - construction methods: how a wardrobe is made

- - how the panels are made

- - types of finishes

- - design types

- - doors: models and opening systems

Construction methods: how is a wardrobe made?

It’s important to understand that there are no fixed rules, only characteristics which allow us to recognise and distinguish between high-quality and low-quality wardrobes.

Let's start with the basics.

There are various methods for constructing a wardrobe, which can be differentiated based on their structural components. The structural panels form the wardrobe’s ‘shell’ and can be categorised as follows:

- - sides: side panels on either end and vertical internal dividers

- - bases or bottoms: lowest shelf panels which close off the bottom of the wardrobe

- - tops: highest shelf panels which close off the top of the wardrobe

- - backs: panels which close off the back of the wardrobe

- - internal shelves

- - doors: which close off the wardrobe at the front and are available in several different models, depending on the type of closing system (hinged or sliding doors)

How the panels are made

How the panels are made depends on the materials used.

Wardrobes made from wood particles and MDF

If it’s of good quality, wood chipboard (or particle board) is a very useful material which is usually either 18, 20, 30 or 36 mm thick. It’s also important to be aware of the various qualitative placements and environmental certifications which, if present, attest to a high level of quality and guarantee salubrity, water repellency, and durability.

This is the case for the V100 panels which, when semi-finished, have a green colour. The standard V100 uses high-quality ureic glues and melamine resins which guarantee a high level of water-resistance.

Another certification is that of the FSC (Forest Stewardship Council) which guarantees the origin of the wood and that it has been felled in a controlled manner. Chipboard is made from leftover scrap wood so it already has quite a low environmental impact.

Another important classification is that which indicates the formaldehyde emissions. The panels are divided into 3 classes (E1, E2 and E3) certified by the european regulations EN 717 and EN 120. The E1 class is considered to be the best and is used in the manufacturing of most Italian-made wardrobes.

Although it has often been mistreated, there’s no need to be wary of this material, which has been produced to last for decades. There are other more important details, such as the ironware, the opening and closing systems, the quality of the edges and surfaces.

MDF (medium density fibreboard) is a similar material to chipboard. It is made up of wood particles which have been reduced to such small fragments that they form a dense, almost paste-like, fibre which gets pressed to the point of having a higher density level than standard chipboard. The paste gets compressed into panels without any superficial imperfections, which are particularly well-suited to lacquering.

Wardrobes made from honeycomb panelling

This construction method involves a solid-wood perimeter frame, inside which they insert a honeycomb structure made of wood or composite materials. The panel is thick, yet light, and is durable over time. This lightness is an added bonus, as the doors will be easy to open and close and won’t weigh down too heavily on the mechanical components, helping them to last longer.

Don’t be fooled...If a panel is light, yet thick, it is an indication of high quality. Often, when a panel or door is heavy, we think that this means it will be stronger or of higher quality. However, it’s often the contrary!

Types of finishes

A wardrobe in melamine or laminate

The panels are covered in melamine paper (sheets of very thin paper impregnated with resin) printed in numerous varieties: wood effect, colourful matt or glossy lacquer effect, white, but also imitating materials such as stone, cement, resin or fabric. In this case, a high-quality melamine / lacquer wardrobe will have a surface which looks very similar to the real thing, whether it’s imitating lacquer, wood veneer or another material. This way, these wardrobes are more affordable than wooden or lacquer models, but are also versatile and practical, with aesthetic characteristics which indicate excellent workmanship.

Wardrobes veneered with real wood

These panels are covered in thin sheets of real wood, typically oak, walnut or cherry. The veneer is either left in its natural colour or is dyed, giving it a finish such as dark oak or wengé. Alternatively, it is also available in open-pore lacquer, in several colours. The wood veneer is so thin that it can even be attached to curved surfaces. The biggest aesthetic advantage of this finish is that each wardrobe will be a one-of-a-kind piece, characterised by its natural (and therefore entirely unique) veining, streaks and shades.

LACCATI

The process of lacquering involves varnishing the panels by hand-spraying them with opaque varnishes (polyester or polyurethane). Once the varnish is applied, the surface is treated by brushing or sanding them in order to get rid of any imperfections or particles. For some models, the panel will then be polished, while others will be left in a matt finish. The lacquer is usually done on MDF panels. There are various colours available and the final result is very neat, with perfect varnished edges and no traces of the joints (as is the case with laminated panels).

Design types

WARDROBES WITH SINGLE PARTITION PANELS

The ‘shoulder’ panels (i.e. side panels and partition panels) of 25 - 26 - 30 mm are mounted vertically and completed with a bottom panel, top panel and shelves. This process continues, adding on additional elements one beside the other until the entire unit is finished off with a final side panel. Lastly, the doors are applied. This is the most common way of building a wardrobe as it is very flexible in terms of both size and design. The aesthetic aspect is also superior to that of wardrobes with double partitions, as discussed below.

Measurements: firstly, there are “singular” elements of 60 - 90 - 120 cm which are composed of just 1 side + base + top, to which we will apply EITHER a final side panel (for wardrobes with one or two doors), OR another element (for wardrobes with 3 or more doors). So, for example, in order to calculate the final measurements, you would add: 120 + 3 cm for the final side panel = total final measurements 243 cm

WARDROBES WITH SEPARATE ELEMENTS AND DOUBLE PARTITION PANELS

In wardrobes of this kind, the side panels of each separate element are lined up next to each other, unlike in the previously-discussed model which features only one partition panel in between each element. This is a reliable system, though it is not as aesthetically pleasing. It is usually used for smaller or more practical storage units (e.g. lockers or small cabinets for utility rooms, storerooms, garages etc.). In short, this is a low-cost solution which prioritises functionality over beauty.

Measurements: if we take, for example, a small wardrobe of 60 cm, it will feature two side panels of 18 mm which are perfectly hidden behind the doors. By combining two elements of this same size, we will have a wardrobe of 60 + 60 = 120 cm. However, when the doors are opened we will be able to see two panels of 18 mm placed next to each other, dividing the inside of the wardrobe.

Doors: opening systems and types

The first factor to consider is the door’s opening system:

- - hinged wardrobes: doors which open with hinges

- - sliding wardrobes: doors which slide over each other, overlapping, and remain staggered when closed

- - coplanar wardrobes: sliding doors with a flush closing system, perfectly aligned when closed

- - built-in wardrobes or wardrobes for an alcove: custom-made systems featuring a framed structure with hooks on the wall and ceiling, to which the doors (hinged, sliding, folding..) are then attached

- - walk-in wardrobes: these are rooms used as closets, and are therefore open wardrobes without doors covering each section. There are several options for the layout of a walk-in wardrobe, i.e. modular systems making up a single structure (which can be a free-standing shell with shelves and various accessories, a wall-mounted rack with wood panelling and shelves which are hooked on, or a structure with floor-to-ceiling uprights, with shelves and storage cabinets)

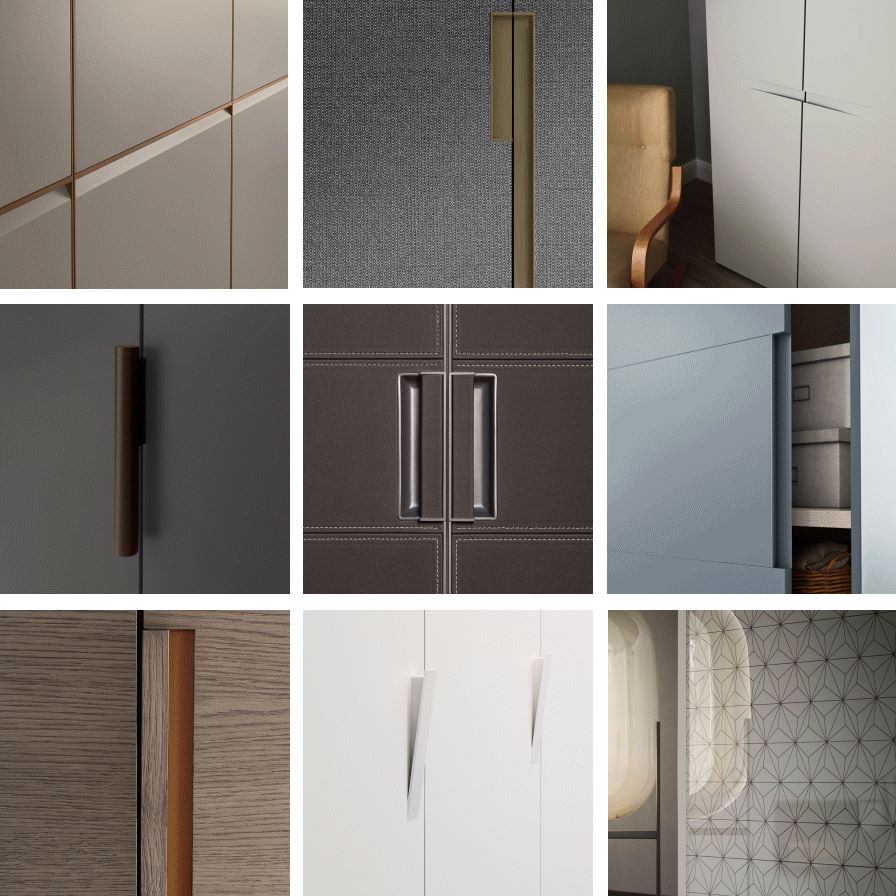

The second factor to consider is the aesthetics of the door and the door handles:

- - smooth doors: the most simple yet versatile option, available in numerous materials and can be personalised with an external or integrated handle

- - groove handles and recess grip handles: these options are not traditional ‘handles’, but a groove or hollow in the side of the door which can be used for opening and closing. They are usually available in various materials and can either span the entire length of the door or just half. This is a purely decorative option, which avoids having handles on the front of the door. You can create contrasts between the materials and colours of the door and of the recess. You can also choose to have a recess handle which is not carved into the door but is simply a groove at the side of the door which is used to open the wardrobe.

- - composite doors: the door panel is made up of more than one material - an aesthetic choice which is particularly suited to sliding doors as they are generally larger than hinged doors

- - engraved doors: doors with a vertical or horizontal engraved panel - this is also an aesthetic choice

- - framed doors: these are usually associated with classic hinged wardrobes, though are also used with sliding wardrobes for a modern effect

A point of interest..

Similarly to the historical context we saw in our guide to sideboards and cupboards, the story of the wardrobe is also closely linked to old residences and aristocratic customs. The etymology of the italian word for wardrobe, ‘armadio’, comes from the latin ‘armarium’, meaning a piece of furniture for storing arms. Luckily, the only weapon we store in our wardrobes today are our stilettos! The english word ‘wardrobe’ (similar to the italian word ‘guardaroba’, a synonym for ‘armadio’), reflects how we use wardrobes today: a place to store ‘robes’ - a word which is associated with the precious clothes worn by nobility.